Some advantages of polished concrete floor surfaces are the long life of its, as well as the virtually unlimited design choices offered. Concrete flooring is excellent for warm climates as it stays cool even in probably the hottest weather conditions. If you're preparing the floor of your office or home to be concreted, there are a handful of things you need to consider.

Images about Concrete Floor Slab Specification

The polished concrete prints fast becoming a typical problem in many places throughout the world and this is partly because numerous men and women are actually appreciative of its beauty as well as because many instances just are not able to stand having any other floor type. Sealed concrete has an incredibly low environmental impact.

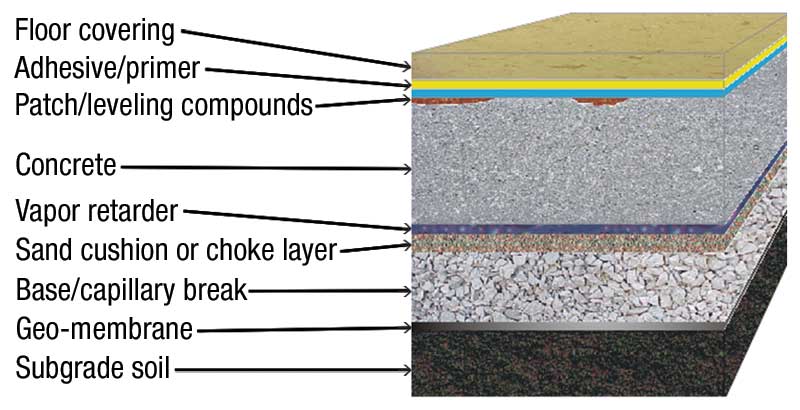

Moisture measurement in concrete floor slabs – Construction Specifier

Developing with concrete countertops out of doors can also be attractive because of the basic maintenance of theirs and huge style flexibility. Concrete polishing is actually the finish of choice for many owners of new and existing concrete floors. Polished concrete is seamless, giving no spot for dust mites to assemble and expose the bacteria which could be caught between tiles and floorboards.

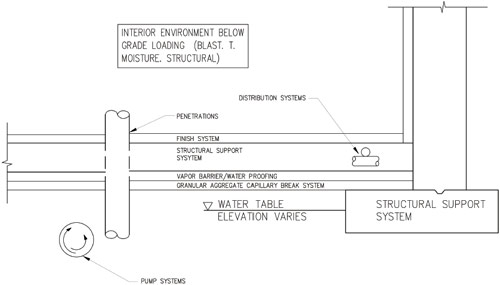

Floor Slabs WBDG – Whole Building Design Guide

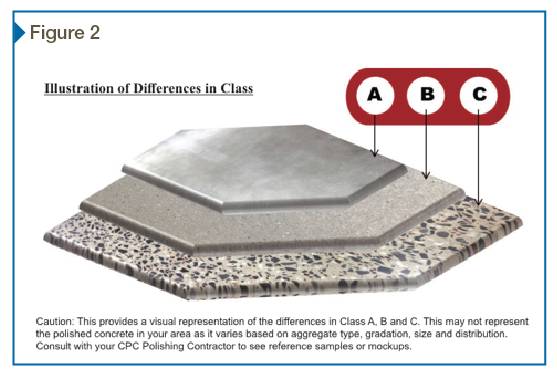

Specifying floor finishes: Polished concrete topping slabs with

Concrete Floor Slab Construction Process – The Constructor

Concrete Topping Slab -Types, Thickness and Uses – The Constructor

Slab On Grade Foundation Design Slab On Grade Design

Polyethylene Under Concrete Slabs – GreenBuildingAdvisor

Building Guidelines Drawings. Section B: Concrete Construction

Building Guidelines Drawings. Section B: Concrete Construction

STRUCTURE magazine Concrete Slabs-on-Ground, Crying for Attention

Building Guidelines Drawings. Section B: Concrete Construction

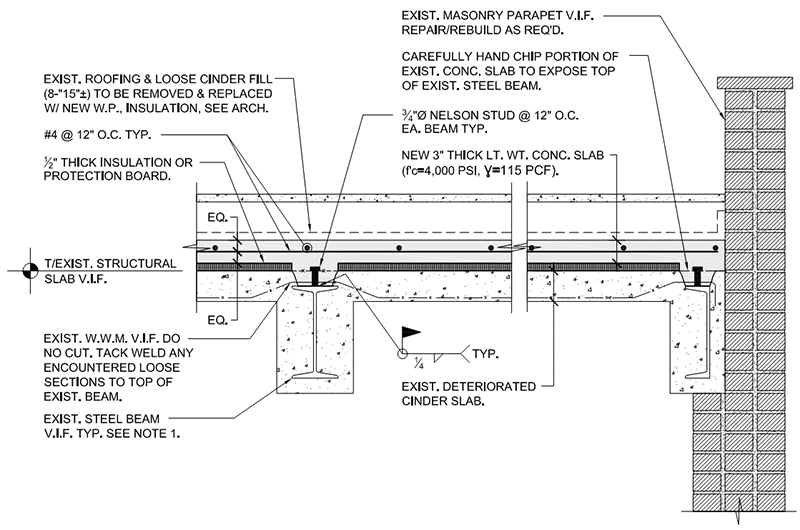

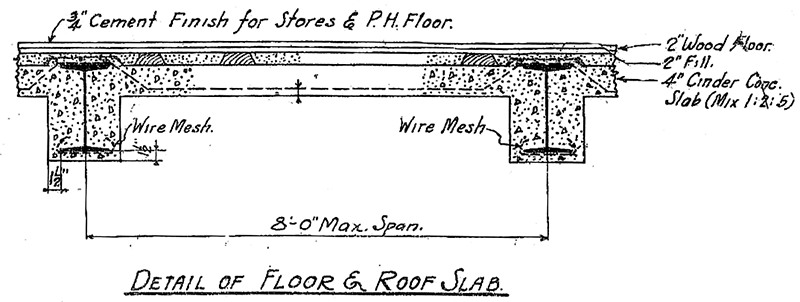

STRUCTURE magazine Cinder Concrete Slab Construction

CONCRETE FLOOR REQUIREMENTS u2013 Automotive Lift Experts

Related Posts:

- Behr Epoxy Concrete Floor Paint

- Concrete Floor Preparation For Wood Flooring

- Epoxy Paint For Concrete Floors Colors

- Rent Concrete Floor Cleaner

- Heated Concrete Floor Tubing

- Concrete Floor Staining Process

- Concrete Floor Interior Design

- Concrete Floors In Your Home

- Cost Of Poured Concrete Floor

- Outdoor Polished Concrete Floors

Concrete Floor Slab Specification: A Comprehensive Guide for Construction Projects

Introduction:

Concrete floor slabs are an integral part of many construction projects, providing a durable and long-lasting foundation for various structures. Whether it’s a residential building, commercial facility, or industrial warehouse, the specifications of a concrete floor slab play a crucial role in ensuring its strength and performance. In this comprehensive guide, we will delve into the various aspects of concrete floor slab specification, including materials, reinforcement, thickness, finishing techniques, and more. So, let’s dive in!

1. Materials for Concrete Floor Slab:

The choice of materials for a concrete floor slab is vital to ensure its structural integrity and longevity. Here are some key considerations when specifying materials:

a) Cement: Use high-quality cement that conforms to relevant standards such as ASTM C150 or EN 197. The type and grade of cement depend on factors like project requirements, environmental conditions, and desired strength.

b) Aggregates: Select well-graded aggregates that comply with ASTM C33 or EN 12620. Coarse aggregates should have a maximum size not exceeding one-fifth the thickness of the slab. It is essential to consider factors such as aggregate shape, size distribution, and moisture content to achieve optimal workability and strength.

c) Admixtures: Depending on the project requirements, various admixtures can be used to enhance the concrete’s properties. These may include plasticizers to improve workability or air-entraining agents for freeze-thaw resistance.

FAQs:

Q1: Can I use recycled aggregates for a concrete floor slab?

A1: Yes, recycled aggregates can be used in certain cases. However, they must meet specific quality criteria and comply with relevant standards to ensure adequate strength and durability.

Q2: What is the advantage of using air-entraining agents in concrete floor slabs?

A2: Air-entraining agents create microscopic air bubbles in the concrete, improving its resistance to freeze-thaw cycles and reducing the risk of cracking.

2. Reinforcement in Concrete Floor Slabs:

Reinforcement plays a crucial role in enhancing the load-carrying capacity and crack resistance of concrete floor slabs. Here are some key considerations when specifying reinforcement:

a) Steel Reinforcement: Use high-quality steel reinforcement bars (rebars) that comply with ASTM A615 or BS 4449. The rebars should have proper yield strength, ductility, and corrosion resistance properties. Additionally, consider factors like bar spacing, lap lengths, and development lengths to ensure adequate structural performance.

b) Mesh or Fibers: In certain cases, steel mesh or synthetic fibers can be used as an alternative or additional reinforcement. Steel mesh provides crack control and distributes loads more uniformly, while fibers improve the concrete’s toughness and reduce plastic shrinkage cracking.

c) Joint Reinforcement: For large floor areas or where control joints are present, joint reinforcement can be specified to provide additional strength and stability. This typically involves using dowels or reinforcing bars across the joints to transfer loads effectively.

FAQs:

Q1: Can I use fiber reinforcement alone without steel rebars?

A1: Fiber reinforcement can be used as the sole reinforcement in certain applications where the loads are relatively low. However, for higher load-carrying capacities, it is advisable to combine fibers with steel rebars for optimal performance.

Q2: What is the recommended spacing for reinforcing bars in a concrete floor slab?

A2: The recommended bar spacing For a concrete floor slab depends on various factors such as the load requirements, slab thickness, and concrete strength. It is important to consult with a structural engineer or refer to relevant design codes and standards to determine the appropriate spacing for your specific project. Reinforcement plays a significant role in enhancing the load-carrying capacity and crack resistance of concrete floor slabs. High-quality steel reinforcement bars (rebars) should be used, meeting specific standards such as ASTM A615 or BS 4449. Factors like bar spacing, lap lengths, and development lengths should also be considered to ensure structural performance.

In certain cases, steel mesh or synthetic fibers can be used as alternative or additional reinforcement. Steel mesh provides crack control and distributes loads more uniformly, while fibers improve toughness and reduce plastic shrinkage cracking.

For large floor areas or where control joints are present, joint reinforcement can be specified to provide additional strength and stability. This involves using dowels or reinforcing bars across the joints for effective load transfer.

Regarding FAQs:

Q1: Fiber reinforcement alone can be used in certain applications with lower loads. However, for higher load-carrying capacities, it is advisable to combine fibers with steel rebars for optimal performance.

Q2: The recommended bar spacing for reinforcing bars in a concrete floor slab depends on factors such as load requirements, slab thickness, and concrete strength. It is important to consult with a structural engineer or refer to relevant design codes and standards to determine the appropriate spacing for a specific project.