But, including the hardest to add flooring is likely to be among the easier issues you will have to do when having a home, and you will be staying away from tough and costly repairs down the road. All types of garage floor coverings will better the appearance of your garage, increase the longevity of its and add to the importance of your house. This's because the rubber flooring includes a low resistance to oil products.

Images about Do It Yourself Garage Floor Epoxy

Additionally in case you occur to spill anything on your new garage flooring you will find it is quite easy to wash it up. You are able to design the look of the garage appear as terrific as any place at the home all with just a bit of color on your garage flooring and walls. They demand reduced maintenance, therefore are extremely popular.

DIY Epoxy Garage Floors

Garage floors are placed to the test on a consistent basis. It will in addition prevent damage from oil, grease and other fluid leaks, extend the life of the floor and make it a lot easier to help keep the garage clean by plugging the porous surface. Obviously, there's always the vaunted checkerboard pattern which you can find on almost all forms of coverings.

DIY Epoxy Garage Floor DIY Divas AutoSavvy

Coatings Pro v. DIY Epoxy Garage Floor Kits CoatingsPro Magazine

How to Resurface a Garage Floor HGTV

How to Epoxy Your Garage Floor in 9 Steps

DIY How-To Renew a Pitted Garage Floor with a Nohr-S Coating All

DIY Epoxy Garage Floors

How to Resurface a Garage Floor HGTV

The Benefits of Epoxy Garage Floor Coatings All Garage Floors

How to Apply Epoxy Coating to a Garage Floor – This Old House

DIY Epoxy Garage Floor Coating Repair – Casper, WY

What makes the best Garage Floor Coating?

DIY Epoxy Garage Floor Coating Repair – Casper, WY

Related Posts:

- Garage Floor Protection Mats

- 1 Bedroom Garage Apartment Floor Plans

- How To Install A Garage Floor Drain

- Garage Floor Stain Colors

- Garage Floor Filler

- Liquid Granite Garage Floor

- Ucoat It Garage Floor Coating

- Epoxy Garage Floor Ideas

- Rustoleum Garage Floor Epoxy Touch Up

- Fast Track Garage Flooring

Do It Yourself Garage Floor Epoxy: A Comprehensive Guide to Achieving a Professional Finish

Introduction:

When it comes to upgrading your garage, one often overlooked aspect is the garage floor. A worn-out, stained concrete floor not only looks unappealing but can also be difficult to clean and maintain. However, with the rising popularity of do-it-yourself (DIY) projects, homeowners now have the opportunity to transform their garage floors into a durable, attractive space with the use of epoxy coatings.

In this article, we will delve into the world of DIY garage floor epoxy and provide you with a comprehensive guide on how to achieve a professional finish. From preparation and materials to application and maintenance, we’ll cover all the essential steps needed to revamp your garage floor.

I. Understanding Garage Floor Epoxy:

Epoxy coatings are made by combining resin and hardener, resulting in a chemical reaction that creates a tough, durable surface. When applied to concrete floors, epoxy can enhance their appearance while providing superior resistance to stains, chemicals, abrasion, and wear.

1. What are the benefits of using epoxy for garage floors?

Epoxy coatings offer numerous advantages for garage floors:

– Durability: Epoxy creates a strong bond with concrete, forming a resilient surface that can withstand heavy loads.

– Chemical resistance: Epoxy coatings are resistant to oil spills, gasoline, household chemicals, and other substances that may damage bare concrete.

– Easy maintenance: Epoxy-coated floors are effortless to clean and maintain due to their smooth finish.

– Enhanced aesthetics: With various color options and the ability to add decorative flakes or metallic effects, epoxy allows you to customize your garage floor according to your preferences.

II. Preparing Your Garage Floor:

Before applying epoxy coatings to your garage floor, proper preparation is crucial to ensure optimal adhesion and longevity of the coating.

1. Cleaning the floor:

Start by removing all items from the garage and thoroughly sweep or vacuum the floor to eliminate dust and debris. Next, clean the surface using a degreaser or detergent specifically designed for concrete. Scrub the floor with a stiff-bristle brush or use a pressure washer to remove any stains, grease, or oil residues. Rinse the floor thoroughly and allow it to dry completely.

2. Repairing cracks and imperfections:

Inspect the floor for any cracks, pits, or other imperfections that may hinder the epoxy application. Fill small cracks with an epoxy patching compound, ensuring that it is level with the surrounding surface. For larger cracks or significant damage, consult a professional before proceeding.

3. Etching the concrete:

To promote better adhesion, it’s essential to etch the concrete surface. This process involves applying an acid-based solution or mechanical grinding to open up the pores of the concrete. Follow the manufacturer’s instructions carefully when using an etching solution, as safety precautions need to be taken.

III. Choosing the Right Epoxy Coating:

Selecting the appropriate epoxy coating for your garage floor is crucial to achieving a professional finish that meets your specific needs.

1. Evaluating epoxy types:

There are two main types of epoxy coatings: water-based and solvent-based.

– Water-based epoxies are more user-friendly, emit fewer odors during application, and have a quick drying time. They are ideal for DIY projects in residential settings.

– Solvent-based epoxies are more durable and resistant to chemicals but can emit strong fumes During application. They are commonly used in commercial or industrial settings.

2. Considering the level of traffic:

The amount of traffic your garage floor will experience should also be taken into account when choosing an epoxy coating. If your garage is primarily used for vehicle parking, a standard epoxy coating should suffice. However, if you anticipate heavy traffic or the use of heavy machinery or equipment, a high-performance epoxy coating may be necessary.

3. Exploring additional features:

Some epoxy coatings offer additional features such as UV resistance, anti-slip properties, or high-gloss finishes. Consider these options based on your specific needs and preferences.

IV. Applying the Epoxy Coating:

Once your garage floor is properly prepared and you have chosen the right epoxy coating, it’s time to apply the coating.

1. Priming the floor:

Before applying the epoxy coating, it’s recommended to prime the floor with a primer specifically designed for epoxy coatings. This will enhance adhesion and ensure a more durable finish.

2. Mixing the epoxy:

Follow the manufacturer’s instructions for mixing the epoxy components together. Thoroughly mix the resin and hardener until they are completely blended.

3. Applying the epoxy:

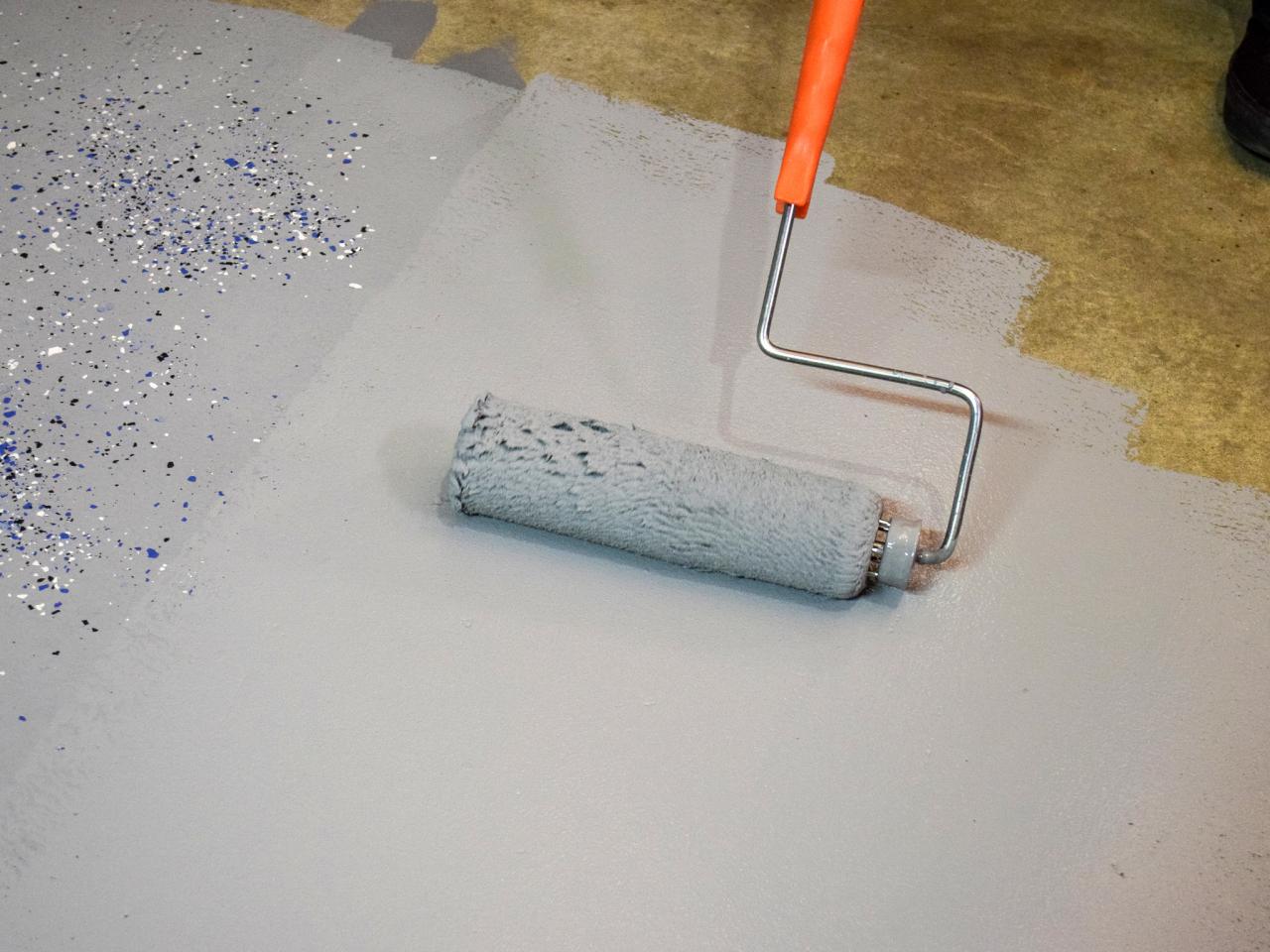

Using a roller or brush, start applying the epoxy coating in small sections of the garage floor. Work in a methodical manner to ensure even coverage and avoid pooling or overlapping strokes. Use a squeegee or roller with a spike to remove any air bubbles that may form during application.

4. Adding decorative flakes (optional):

If desired, you can sprinkle decorative flakes onto the wet epoxy coating to add texture and visual interest. Allow the epoxy to cure for a designated time before proceeding.

5. Applying a topcoat (optional):

To further enhance the durability and appearance of your garage floor, consider applying a topcoat over the cured epoxy. This will provide an extra layer of protection against wear and tear.

V. Curing and Maintaining the Epoxy Coating:

After applying the epoxy coating, it’s important to allow sufficient time for curing and properly maintain the surface to ensure its longevity.

1. Curing time:

Follow the manufacturer’s instructions for the recommended curing time of your epoxy coating. This typically ranges from 24 to 72 hours, depending on the specific product.

2. Avoiding heavy use:

During the curing process and in the days following, avoid subjecting the epoxy-coated floor to heavy loads or excessive traffic. This will allow the coating to fully harden and bond with the concrete surface.

3. Regular cleaning and maintenance:

To maintain the appearance and functionality of your epoxy-coated garage floor, regularly sweep or vacuum to remove any dirt or debris. Clean up spills promptly using mild detergents or cleaners specifically formulated for use on epoxy coatings. Avoid using abrasive materials or harsh chemicals that may damage or dull the surface.

Overall, using epoxy coatings for garage floors offers numerous benefits, including durability, chemical resistance, easy maintenance, and enhanced aesthetics. By properly preparing your garage floor, choosing the right epoxy coating, applying it correctly, and maintaining it regularly, you can enjoy a long-lasting and visually appealing garage floor.