Epoxy coatings will react with previously installed coatings. Simply by adding a work bench and some epoxy flooring covering you've a professional looking project along with a floor that could be enjoyed for decades to come. You may be thinking off introducing a shop or converting the garage of yours into a work shop. The best thing about epoxy is that it creates an eye-catching yet easy appearance.

Images about Epoxy For Boat Floor

Epoxy floors coating is a flooring surface area made up of several tiers of epoxy applied to the floor to a range of under two millimeters. Epoxy seamless is actually a great idea for manufacturing workshop, garage and also for kid's bedroom flooring to go over dull, gray concrete and provide you with protected, appealing, easy to surfaces that are clean.

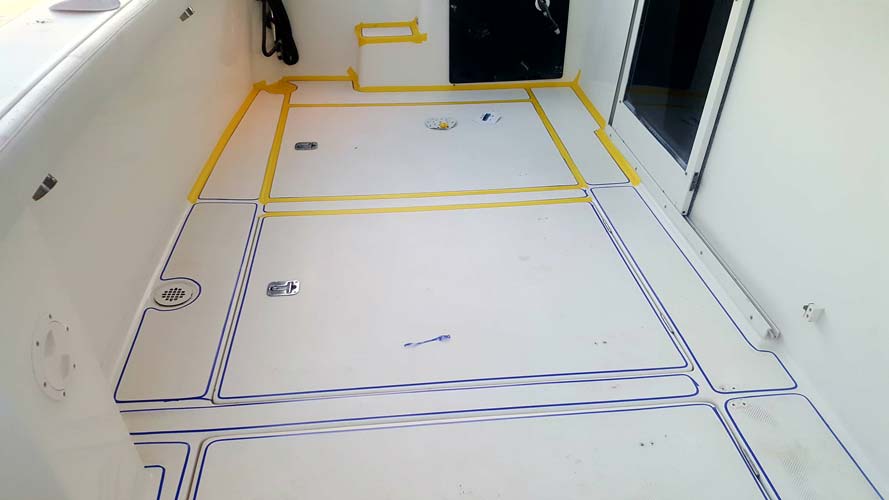

Fiberglass Boat Deck Refinishing with Polyaspartic Coating Slide

When this happens, there is absolutely nothing you are able to do to correct the problem. Even if there is a bit of wear and tear above your surfacing you are able to easily repair them with the epoxy floor paints. In the event the affected region is a small portion, you don't have to stress with the exact shade of color. The personalization of epoxy floor surfaces does not stop at basecoat.

Fiberglass Boat Deck Refinishing with Polyaspartic Coating Slide

The color choices are only constrained by the business enterprise that offers them. Most of these characteristics give longer longevity of surfaces. Using your very own epoxy flooring to a business building or an area in your house might be easier than expected. High grade epoxy resin is used to update surfaces, obtain colored effects, protect floor surfaces against corrosion, and attain a water tight outcome.

Fiberglass Boat Deck Refinishing with Polyaspartic Coating Slide

Slip-Resistant Maritime Decking for Boats, Ferries, Ships u0026 Tankers

Slip-Resistant Maritime Decking for Boats, Ferries, Ships u0026 Tankers

Boat floor coatings Boat Design Net

Applying an epoxy coating to a wooden boat – YouTube

Clear Interior Marine Epoxy SynDeck® IMO Epoxy SS5000 Clear

Boat Transom and Floor Rebuild – Using the Epoxy Thickening Compound – Part 46

E650 Non-Skid Epoxy Floor u0026 Deck Low Temp 25°F OSHA ADA Navy Spec Mil-PRF-24667B

Which Epoxy Should I Use For My Project? u2013 TotalBoat

Garage Floor Coatings u0026 Storage Photo Gallery Slide-Lok garage

KiwiGrip Non-Skid Coating

Related Posts:

- Gray Epoxy Floor

- Epoxy Garage Floor Crack Filler

- Behr Epoxy Floor Paint

- High Build Epoxy Floor Coating

- Cost To Have Someone Epoxy Garage Floor

- Epoxy Shield Floor Paint

- Rustoleum Epoxy Basement Floor Paint

- What Is Epoxy Flooring Systems

- Austin Epoxy Floors

- Alternative To Epoxy Flooring

Epoxy For Boat Floor: Enhancing Durability and Aesthetics

Introduction:

When it comes to maintaining and improving the performance of your boat, paying attention to the flooring is essential. The boat floor withstands constant exposure to water, sunlight, and other environmental factors that can lead to wear and tear over time. To combat this, many boat owners turn to epoxy as a reliable solution for protecting and enhancing their boat floors. In this comprehensive guide, we will delve into the world of epoxy for boat floor applications, exploring its benefits, application process, and frequently asked questions.

I. Understanding Epoxy Coating for Boat Floors:

Epoxy coating is a durable and versatile option for boat flooring that offers numerous advantages over traditional materials. It is a two-part system consisting of resin and hardener that chemically react when combined. This reaction creates a strong bond with the surface, forming a seamless, protective layer that can withstand heavy foot traffic, impacts, chemicals, and UV rays.

The Benefits of Epoxy Coating for Boat Floors:

1. Enhanced Durability: Epoxy coating significantly improves the durability of boat floors by providing a tough and resilient surface. It acts as a barrier against scratches, dings, and other types of damage caused by regular use.

2. Water Resistance: One of the primary concerns with boat floors is water damage. Epoxy coating effectively seals the surface, preventing water penetration and minimizing the risk of rot or mold growth.

3. UV Protection: Prolonged exposure to sunlight can fade or discolor boat floors over time. Epoxy coatings contain UV inhibitors that shield the surface from harmful UV rays, preserving its appearance for longer periods.

4. Chemical Resistance: Boats often come into contact with various chemicals such as gasoline, diesel fuel, or cleaning agents. Epoxy coatings are resistant to these substances, ensuring that your boat floor remains unharmed.

II. Applying Epoxy Coating on Boat Floors:

Before applying epoxy coating, it is crucial to ensure that the boat floor is clean, dry, and free from any contaminants. Follow these steps for a successful epoxy application:

1. Surface Preparation:

a. Remove Existing Coatings: If there are any existing coatings or sealants on the boat floor, they must be completely removed before applying epoxy. Use a chemical stripper or mechanical methods such as sanding or grinding to achieve a clean surface.

b. Clean Thoroughly: Remove all dirt, grease, oil, and other debris from the boat floor. Scrub the surface with a mild detergent and rinse with water. For stubborn stains, use a degreaser or solvent and scrub with a stiff brush.

c. Repair Any Damage: Inspect the boat floor for cracks, holes, or other damage. Fill these areas with an appropriate marine-grade filler and sand them smooth once dry.

2. Primer Application:

a. Choose the Right Primer: Select an epoxy primer specifically designed for marine applications. This primer will enhance adhesion and ensure the longevity of the epoxy coating.

b. Apply Primer: Follow the manufacturer’s instructions to apply the primer evenly across the entire boat floor using a roller or brush. Allow sufficient drying time as specified by the product guidelines.

3. Epoxy Coating Application:

a. Mix Epoxy Components: Thoroughly mix the epoxy resin and hardener according to the manufacturer’s recommended ratio in a clean container. Stir gently but thoroughly to avoid introducing Air bubbles into the mixture.

b. Apply Epoxy: Using a roller or brush, apply the epoxy coating evenly onto the boat floor. Work in small sections to ensure complete coverage. Avoid over-applying as it can lead to pooling or uneven surfaces.

c. Smooth Out: After applying the epoxy, use a foam roller or brush to smooth out any imperfections or air bubbles. This will help create a seamless and professional-looking finish.

d. Allow Drying Time: Follow the manufacturer’s instructions for drying time. Typically, epoxy coatings require at least 24 hours to cure fully. Ensure proper ventilation during this time to aid in the curing process.

e. Apply Additional Coats (Optional): Depending on the desired finish and level of protection, you may choose to apply additional coats of epoxy. Follow the same application process, allowing sufficient drying time between each coat.

f. Final Inspection: Once the epoxy coating is fully cured, inspect the boat floor for any missed spots or imperfections. Touch up these areas as necessary.

III. Maintenance Tips for Epoxy-Coated Boat Floors:

1. Regular Cleaning: To maintain the appearance and durability of your epoxy-coated boat floor, regularly clean it with a mild detergent and water solution. Avoid using abrasive cleaners or scrub brushes that may damage the coating.

2. Avoid Harsh Chemicals: While epoxy coatings are resistant to most chemicals, it is still advisable to avoid prolonged exposure to harsh substances such as gasoline or solvents. Wipe off any spills immediately to prevent potential damage.

3. Protect from Heavy Objects: Avoid dropping heavy objects or dragging sharp items across the boat floor, as this can cause scratches or dents in the epoxy coating.

4. Periodic Inspection: Regularly inspect the epoxy-coated boat floor for any signs of wear, peeling, or damage. Address any issues promptly to prevent further deterioration.

By following these guidelines and properly maintaining your epoxy-coated boat floor, you can enjoy its enhanced durability and aesthetic appeal for years to come.