It's a good idea to use furniture protectors, flooring mats, and area rugs to guard the wood floors of yours from scratches. An oak wood flooring is a good option since it's very difficult and works very well in areas which get a lot of site traffic, but you can find a handful of things you ought to be aware of before you select the hardwood flooring of yours.

Images about How Thick Is Engineered Wood Flooring

Hundred years ago, hardwood floors happened to be, for probably the most part, the only flooring type attainable on the public. Other than creating a new sort of finish to give it much more protection, there is not much that can be done to change its profile. A sensation of history from a time when working with solid wood flooring was the way a home was built.

EXPERT Engineered – Lauzon Hardwood Flooring

Reclaimed woods are steeped inside historical past. With hardwood flooring not a good deal has altered since the 70s to enhance it's tolerance of regular living conditions. With ease of maintenance and also a wide array of shopping venues, having an engineered wood flooring has never been easier. Darker colors are also ideal for bedrooms and office rooms, however, the wood should be stronger since these rooms contain significant furniture that's likely to be moved often.

How Thick Should Engineered Wood Flooring Be? PRO! Flooring

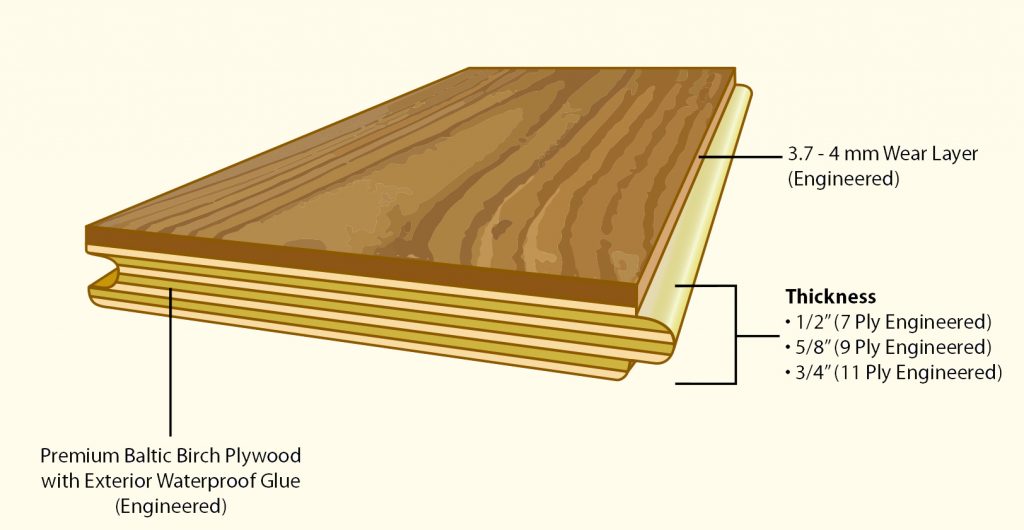

3/4″ Inch Thick Engineered. Baltic Birch Ply – 5.8 mm Wear Layer

What should be the Right Thickness of your Next Engineered Wood

All About Engineered Wood Flooring

All About Engineered Wood Floors – This Old House

/cdn.vox-cdn.com/uploads/chorus_asset/file/19489671/02_about_wood_floors_x.jpg)

3/4 Inch Engineered 2019

Engineered Hardwood Floors Keri Wood Floors

20/6mm Thickness 190mm Wide EU Oak Engineered Wood Flooring with

Engineered Hardwood Flooring Installation Charlotte NC

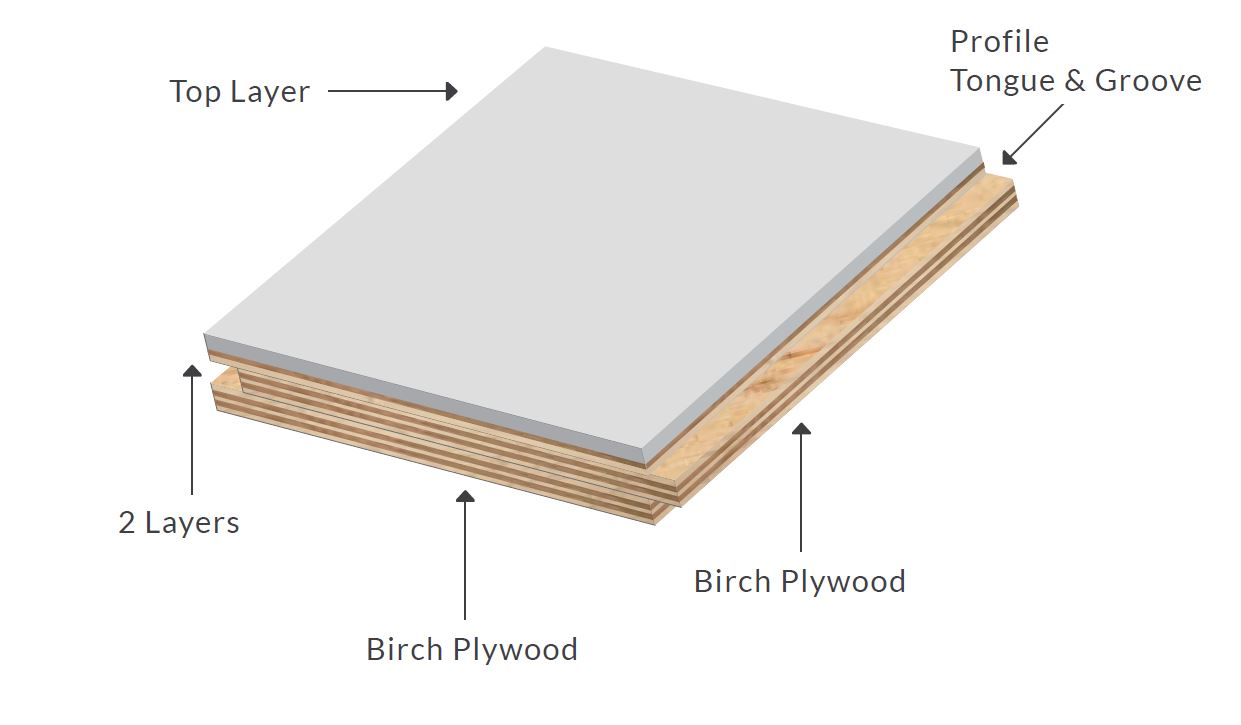

3-LAYER Tu0026G ENGINEERED FLOORING Thickness 15 mm coswick.com

6 Questions about Engineered Hardwood Floors Peachey Hardwood

5 Proven Hardwood Flooring Thickness Categories u2013 Easiklip Floors

Related Posts:

- Canadian Maple Engineered Wood Flooring

- Bordeaux Pine Wood Flooring

- Reclaimed Wood Flooring Ideas

- White Wood Floor Bathroom

- Outdoor Wood Flooring Planks

- Wood Floor Sealing Options

- Bamboo Solid Wood Flooring Reviews

- Wood Floors White Baseboards

- Can You Use Engineered Wood Flooring In A Bathroom

- Wood Floor Out Of Pallets

How Thick Is Engineered Wood Flooring

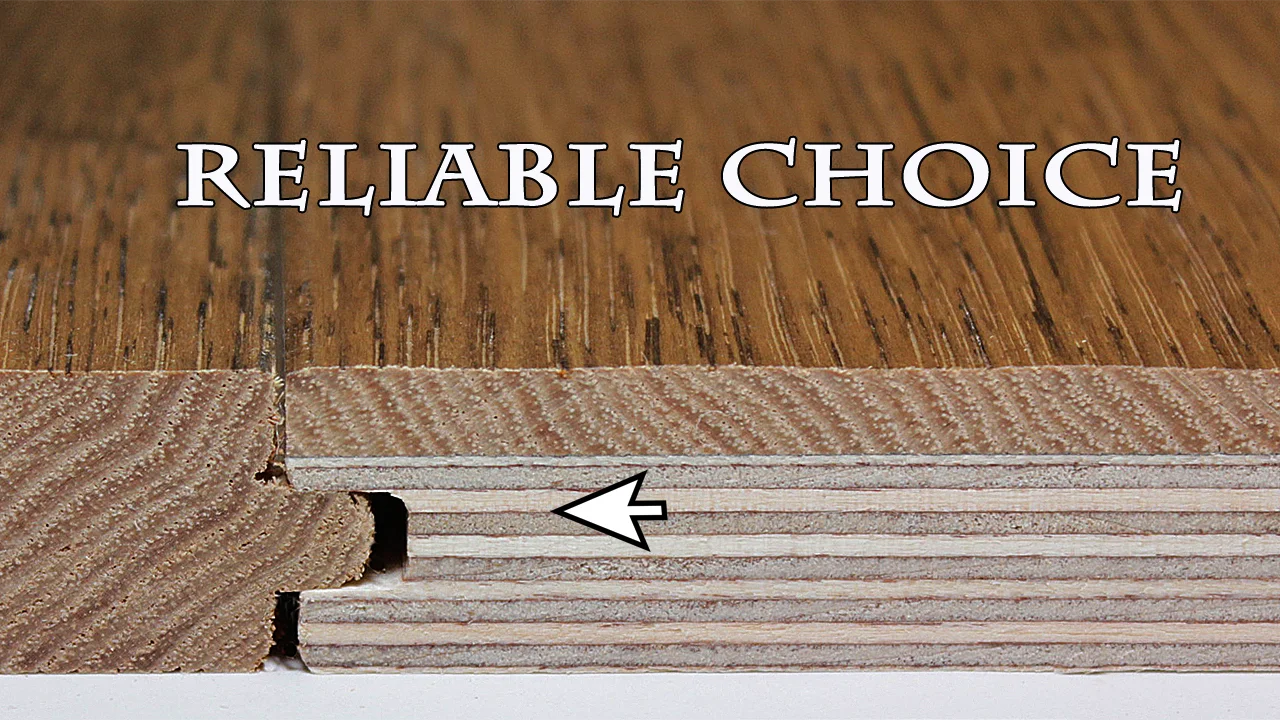

Engineered wood flooring has gained popularity in recent years due to its durability, versatility, and aesthetic appeal. Unlike solid hardwood flooring, which is made from a single piece of wood, engineered wood consists of multiple layers of wood veneer that are bonded together to create a stable and durable flooring option. One important factor to consider when choosing engineered wood flooring is its thickness. In this article, we will explore the various thickness options available for engineered wood flooring and discuss their advantages and disadvantages.

1. Understanding Engineered Wood Flooring

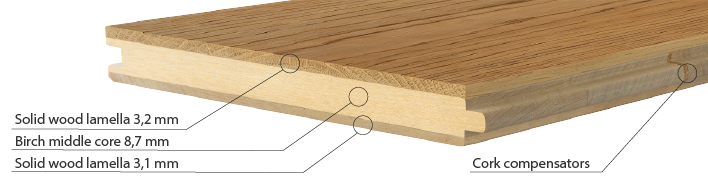

Before delving into the thickness options, let’s first understand what engineered wood flooring is and why it has become a popular choice for homeowners and designers alike. Engineered wood flooring is composed of several layers: a top layer (wear layer) made of real hardwood veneer, multiple core layers made of plywood or high-density fiberboard (HDF), and a bottom layer (backing) that provides stability. These layers are tightly bonded together using heat and pressure to create a strong and durable plank.

2. Standard Thickness Options

Engineered wood flooring is available in various thicknesses to suit different installation requirements and preferences. The most common thickness options are as follows:

a. 3/8″ (9mm)

This is the thinnest option available for engineered wood flooring. It is often chosen for remodeling projects where height restrictions play a role. Although it may not offer the same level of stability as thicker options, it can still provide a durable and visually appealing floor.

b. 1/2″ (12mm)

The 1/2″ thickness is considered standard for engineered wood flooring. It strikes a balance between stability and affordability, making it a popular choice among homeowners. This thickness option can withstand moderate foot traffic and can be installed in most residential areas.

c. 5/8″ (15mm)

For areas with heavy foot traffic or commercial applications, a thicker engineered wood flooring option is recommended. The 5/8″ thickness provides enhanced stability and durability, making it suitable for high-traffic areas such as offices, retail stores, and restaurants.

d. 3/4″ (19mm)

The 3/4″ thickness is the thickest option available for engineered wood flooring. It offers maximum stability and can withstand heavy foot traffic and intense wear and tear. This thickness option is commonly used in commercial settings where durability is of utmost importance.

3. Factors to Consider When Choosing Thickness

When deciding on the thickness of your engineered wood flooring, several factors should be taken into account:

a. Subfloor Condition

The condition of your subfloor plays a crucial role in determining the appropriate thickness of your engineered wood flooring. If you have a concrete subfloor, a thicker plank may be required to ensure proper stability and minimize the risk of warping or buckling. On the other hand, if you have a wooden subfloor, a thinner plank may suffice.

b. Foot Traffic

Consider the amount of foot traffic your floor will endure on a daily basis. For residential areas with low to moderate foot traffic, a 1/2″ thickness should suffice. However, for high-traffic areas or commercial applications, it is advisable to opt for a thicker option like 5/8″ or 3/4″ to ensure long-lasting durability.

c. Acoustic Requirements

If noise reduction is a concern in your space, such as in multi-story buildings or apartments, you May want to consider a thicker engineered wood flooring option. Thicker planks have better acoustic properties and can help reduce sound transmission between floors.

d. Height Restrictions

In some cases, there may be height restrictions that limit the thickness of your engineered wood flooring. This is commonly seen in remodeling projects where the new flooring needs to align with existing flooring or door thresholds. In such cases, a thinner option like 3/8″ may be necessary.

e. Budget

Lastly, your budget will also play a role in deciding the thickness of your engineered wood flooring. Thicker options tend to be more expensive due to the additional materials used and increased stability. Consider your budgetary constraints and prioritize accordingly.

Overall, choosing the right thickness for your engineered wood flooring depends on factors such as subfloor condition, foot traffic, acoustic requirements, height restrictions, and budget. By considering these factors carefully, you can select the appropriate thickness that meets your specific needs and ensures a long-lasting and visually appealing floor. To summarize, the thickness of engineered wood flooring can range from 3/8″ to 3/4″. The 3/4″ thickness is the thickest option and offers maximum stability and durability, making it suitable for commercial settings with heavy foot traffic. Factors to consider when choosing the thickness include the subfloor condition, foot traffic, acoustic requirements, height restrictions, and budget. By considering these factors, you can select the appropriate thickness that meets your specific needs.